Reconstruction 1946–1959

At the end of the second world war, Bosch had lost its international sites for the second time. Large parts of its production facilities lay in ruins. The two following decades were devoted to reconstruction, but also to harnessing new lines of business.

With handcarts and shovels — reconstruction at Bosch

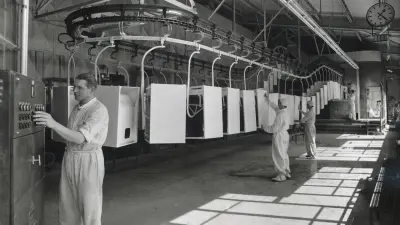

By 1945, more than 50 percent of the Bosch plant facilities in Germany had been destroyed by Allied bombs. Its key role as a wartime supplier of military vehicles had made Bosch a strategic target. Now the company had to clear up, construct, and create work for the associates.

Spark plugs and saucepans — surviving the postwar period

In order to be able to re-employ the associates and pay their wages, Bosch got going again by manufacturing cooking pots from steel helmets, handcarts, and umbrellas in the factory ruins. Associates could either use these appliances themselves or trade them for other essentials. The first more complex products were spark plugs — for the Allies’ military vehicles.

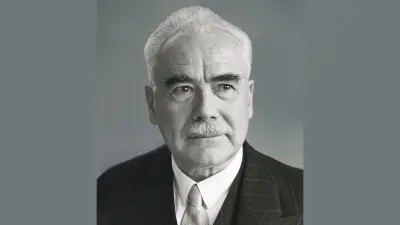

Executor of Robert Bosch’s will and chairman of the board of management

Robert Bosch had died in 1942. The executors of his estate reconstructed the company according to his wishes and testament post-1945. The aim was to generate profit, but also to channel some of this surplus into charitable causes. Hans Walz ran the company as the successor of its founder till 1963.

Antitrust proceedings — the fear of losing everything

The National Socialists’ aspirations to global power had only been achievable with the aid of mighty economic companies. Which is why the Allies sought to break up large German corporations, including Bosch. However, the company had grown organically, which meant its individual parts were not viable on their own. In the end, the Bosch company remained almost intact, although it had to disclose its patents for all competitors to use.

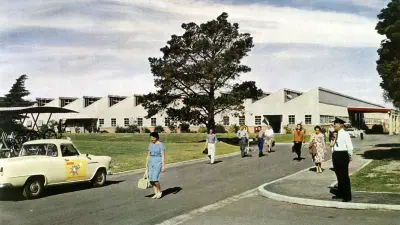

“Made all over the world” — new pathways to an international company

Before Hitler seized power, more than 50 percent of Bosch sales came from international business. But after 1945 it was almost zero, and the company’s international assets had been expropriated. Thanks to good relations with longstanding partners and because of fast-growing markets in countries such as Brazil and India, the construction of a global network gradually took off. All the same, it would take until 1960 for international sales to once again exceed 20 percent at Bosch.

Elegance in perfection — consumer technology

In the early 1950s, Bosch brought products to market that reflected the German and European economic miracle and satisfied the people’s consumer demands as hard times drew to a close. Examples included kitchen appliances and power drills for do-it-yourselfers. Linchpin products such as car radios sold in their millions.

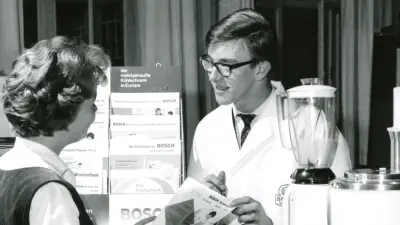

Bosch kitchen appliance

A “new era” dawns in the kitchen

The Bosch food processor was called two key things at its launch. The name of this model was “Neuzeit” and it was heralded as the “countrywoman’s helper”. Customers in urban environments were promised a new era of cutting-edge household technology that would simplify domestic chores.

The appeal to rural households was how much easier this machine would make processing large volumes of food. One reason was the prevalence of large households with many children, another the need to quickly prepare harvests of fruit and vegetables quickly to preserve them for later use — for instance by freezing portions of the produce or making jams and preserves.

The “Neuzeit” was a multi-function device that could cut, knead dough, grate, press, and even peel potatoes.

Photo: Sales scenario for the food processor at the Stuttgart sales outlet (1962)

Re-establishing old favorites — gasoline injection in automobiles

The technology used in many Bosch products still stemmed from the pre-war era. But it would take innovations in order to become and remain competitive. Gasoline injection, which Bosch had developed for aircraft engines, appeared as an innovation in automobiles at the start of the 1950s, although it took decades to take hold as standard.

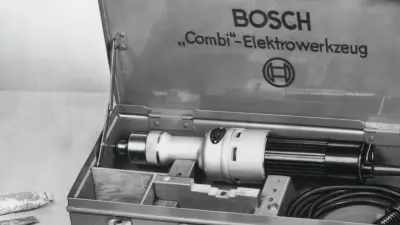

The Bosch Combi

The home power tool

The do-it-yourself craze became a lucrative business for Bosch. Launched in 1952, the “Bosch Combi” electric power tool could be used in many different ways according to the chosen attachment — as a drill, screwdriver, sander, or even a hedge-cutter. This offering spawned a completely new business segment in Europe for what was still mainly male purchasing power — “do-it-yourself”, which took place mainly in cellars and garages.

The complete kit with standard attachments was sold in a case or in a wooden cabinet for wall-mounting. Bosch developed a second key line of power tools this way, to complement its professional power tools range for construction sites, including hammer drills.

Photo: A “Bosch Combi” for do-it-yourselfers — with its practical carry case (1952)

Electronics — a line of business with consequences

Bosch began developing electronic components in the mid-1950s. The first of these was the “variode”, which Bosch started producing in 1958. Transistors followed suit, and then from 1970 integrated circuits. Viewed critically by skeptics but enthusiastically developed by their proponents, they sowed the first seed in the field of electronics, which is now a core business for Bosch.